A: It depends.If we have bulk goods in stock, we can ship goods within 3 days after the QC process. If we don’t have stock, normally it takes 7-15 days for OEM samples and 20-30 days for bulk goods. If it refers to opening the new mold, it takes an extra 7-15 days to make the mold.

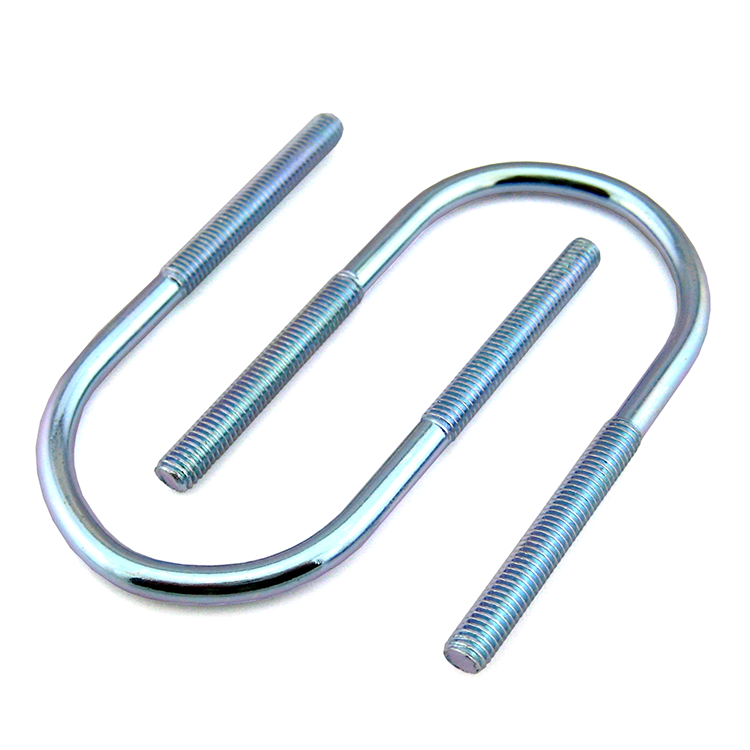

U-Bolt

U-Bolt

Standard Spec :DIN3570,IFI136,EN13411,ASME B 18.31.5

Diameter :M4-M24(8#-1″)

Length:6-1000mm

Material:Carbon Steel ,Alloy Steel ,Stainless Steel

Class:4.8,5.8,6.8,8.8,10.9,G2,G5,G8,A2-70,A4-70

**U-Bolts: Overview**

**Material**:

– **Common materials**:

– **Carbon steel**: Grade 4.8/8.8 (general use), Grade 10.9 (high strength), often zinc-plated or hot-dip galvanized for corrosion resistance.

– **Stainless steel**: 304/316 for marine, chemical, or outdoor environments.

– **Alloy steel**: Heat-treated for heavy-duty applications (e.g., ASTM A193 B7).

– **Surface treatments**: Electro-galvanizing, Dacromet coating, epoxy coating, or powder coating for enhanced durability.

**Manufacturing Process**:

1. **Cold Heading**: Forms the threaded ends and straight shank from steel rod.

2. **Bending**: Hydraulic or CNC bending machines shape the U-profile with precise radius and leg alignment.

3. **Thread Rolling**: Cold-forming threads on both ends for high fatigue resistance (metric/SAE).

4. **Heat Treatment**: Quenching and tempering (for high-grade steel) to achieve hardness (HRC 22-40).

5. **Surface Finishing**: Coating application to meet environmental requirements.

**Key Production Considerations**:

– **Bend consistency**: Uniform radius and leg parallelism (±1° tolerance) to ensure proper clamping force.

– **Thread integrity**: Avoid thread deformation during bending; use protective sleeves if needed.

– **Material selection**: Match strength and corrosion resistance to application (e.g., stainless steel for saltwater).

– **Coating adhesion**: Ensure full coverage, especially on bends, to prevent rust initiation.

**Applications**:

– **Automotive**: Suspension systems, exhaust mounts, leaf spring retention.

– **Pipelines**: Securing pipes to supports in oil/gas, water, and HVAC systems.

– **Marine**: Boat trailers, deck fixtures, and rigging hardware.

– **Construction**: Steel beam clamping, scaffolding, and structural bracing.

– **Agriculture**: Tractor attachments, implement frames, and irrigation systems.

**Installation**:

1. **Alignment**: Position the U-bolt around the pipe, beam, or component to be clamped.

2. **Pad placement**: Insert rubber or metal pads between the U-bolt and clamped surface to prevent damage.

3. **Nut tightening**: Thread nuts onto both ends and tighten gradually in a crisscross pattern.

4. **Torque control**: Apply manufacturer-specified torque (e.g., 50–200 Nm for M12–M24 bolts) to avoid over-compression.

5. **Inspection**: Check for even pressure distribution and re-torque after initial load cycles.

**Note**:

– **Load capacity**: Select U-bolt size/material based on clamping force and environmental exposure.

– **Corrosion management**: Use stainless steel or double-coated U-bolts in humid/chemical environments.

– **Reuse**: Avoid reusing U-bolts with bent legs or thread damage to ensure structural integrity.

*Ideal for mechanical engineers, contractors, and fabricators requiring robust clamping solutions for cylindrical or irregularly shaped components.*

—

**Key Terms**: U-Bolts, Pipe Clamps, DIN 3570, ASTM F468, Corrosion-Resistant U-Bolts.

**Character Count**: Optimized for technical clarity and brevity.

Frequently Asked Questions

A: Normally, we make a 30% deposit after Pl confirmation and a 70% balance before shipment. lf order amountis too small, we can also change to 100% deposit in order to save bank handling charge.

A: A pre-bulk sample check can solve this problem to the largest extent. We will arrange production according to the pre-bulk sample quality standard after your confirmation of the samples.

A: We are not only a trading company but also a manufacturer. Our factory mainly focuses on mold design and quality inspection. Our bulk production may come from the factories we have worked with for a long time, and they are all ISO9001 certified. Through this cooperation model, we can not only ensure product quality and service, but also satisfy the diversified product needs of customers, and the price is more advantageous.

A: Yes,we are very glad to offer you samples.

However the express courier cost from our company to your required address will be upon your account.

Usually we use DHL, UPS, FEDEX or EMS as the courier.

It will take 3-7 days to arrive many Europe countries and North America.

Which express courier we will use, it’s up to your convenient or the express charge.

A: No,just part of our capable categories have been showed in our site.

If you are looking for relative industrial products, please feel free to contact us.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.