A: It depends.If we have bulk goods in stock, we can ship goods within 3 days after the QC process. If we don’t have stock, normally it takes 7-15 days for OEM samples and 20-30 days for bulk goods. If it refers to opening the new mold, it takes an extra 7-15 days to make the mold.

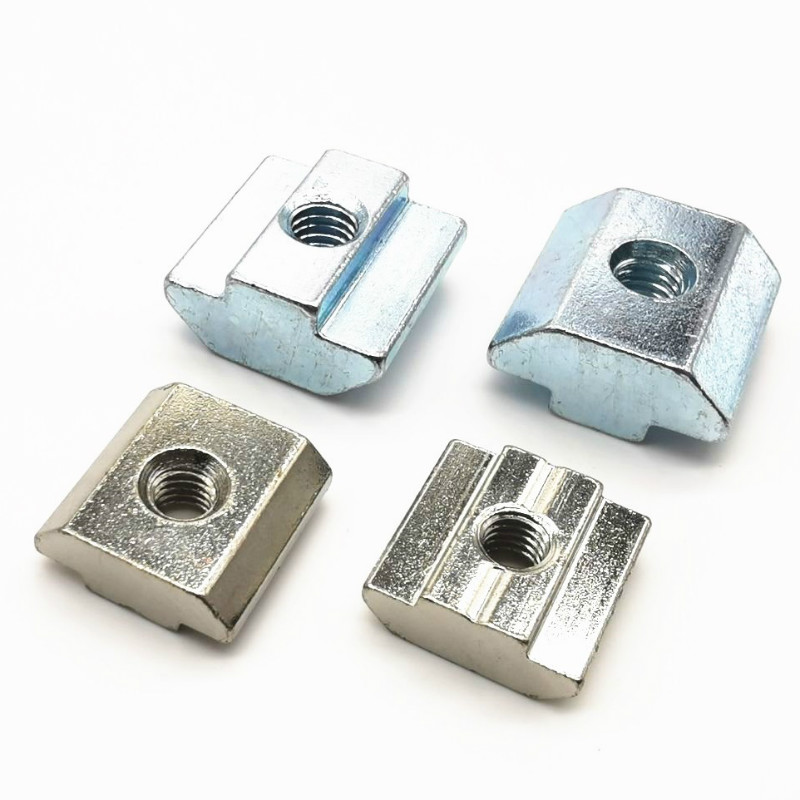

Stop washer

Stop washer

Standard Spec :DIN432,DIN463,DIN93,GB854,GB855,GB856

Diameter :M2-M52(4#-2”)

Material:Carbon Steel ,Alloy Steel ,Stainless Steel

Class:4.8,5.8,6.8,8.8,10.9,G2,G5

Retaining Washers: Overview

Materials:

- Stainless steel (AISI 304/316 for corrosion resistance), carbon steel (high strength, heat-treated), alloy steel (heavy-duty applications), or phosphor bronze (non-sparking, electrical applications).

- Surface treatments: Zinc plating, galvanization, or Dacromet coating for rust prevention and wear resistance.

Manufacturing Process:

- Stamping/Punching: Cut washer blanks from metal sheets with precise inner/outer diameters.

- Forming: Create features like tabs, teeth, or lugs using dies for axial retention.

- Heat Treatment: Hardening (for steel washers) to enhance durability and elasticity.

- Surface Finishing: Apply coatings or passivation to improve corrosion resistance.

Key Production Considerations:

- Dimensional Precision: Ensure tight tolerances for inner/outer diameters to fit shafts or fasteners.

- Feature Sharpness: Maintain sharp edges on teeth or tabs for effective grip.

- Deburring: Smooth edges to prevent damage to mating surfaces.

- Material Uniformity: Avoid internal defects (e.g., voids or cracks) during forming.

Applications:

- Industrial Machinery: Secure bearings, gears, or pulleys on shafts.

- Automotive: Retain components in transmissions, wheel hubs, or steering systems.

- Aerospace: Prevent axial movement in high-vibration assemblies.

- Electronics: Fix rotating parts in motors or actuators.

- Construction: Stabilize fasteners in structural frameworks.

Installation:

- Positioning: Slide onto the shaft or fastener, aligning tabs/teeth with grooves or slots.

- Securing: Bend tabs against flat surfaces or use a retaining ring plier for circlips.

- Torque: Follow manufacturer specs to avoid deformation.

- Inspection: Ensure washer sits flush and engages fully with retention features.

Advantages:

- Prevents axial displacement in dynamic or rotating systems.

- Reusable in non-critical applications (if undamaged).

- Compact design for space-constrained assemblies.

Note:

- Avoid reuse in high-stress applications if deformation or wear is visible.

- Pair with groove pins or snap rings for redundant retention in critical systems.

Frequently Asked Questions

A: Normally, we make a 30% deposit after Pl confirmation and a 70% balance before shipment. lf order amountis too small, we can also change to 100% deposit in order to save bank handling charge.

A: A pre-bulk sample check can solve this problem to the largest extent. We will arrange production according to the pre-bulk sample quality standard after your confirmation of the samples.

A: We are not only a trading company but also a manufacturer. Our factory mainly focuses on mold design and quality inspection. Our bulk production may come from the factories we have worked with for a long time, and they are all ISO9001 certified. Through this cooperation model, we can not only ensure product quality and service, but also satisfy the diversified product needs of customers, and the price is more advantageous.

A: Yes,we are very glad to offer you samples.

However the express courier cost from our company to your required address will be upon your account.

Usually we use DHL, UPS, FEDEX or EMS as the courier.

It will take 3-7 days to arrive many Europe countries and North America.

Which express courier we will use, it’s up to your convenient or the express charge.

A: No,just part of our capable categories have been showed in our site.

If you are looking for relative industrial products, please feel free to contact us.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.