A: It depends.If we have bulk goods in stock, we can ship goods within 3 days after the QC process. If we don’t have stock, normally it takes 7-15 days for OEM samples and 20-30 days for bulk goods. If it refers to opening the new mold, it takes an extra 7-15 days to make the mold.

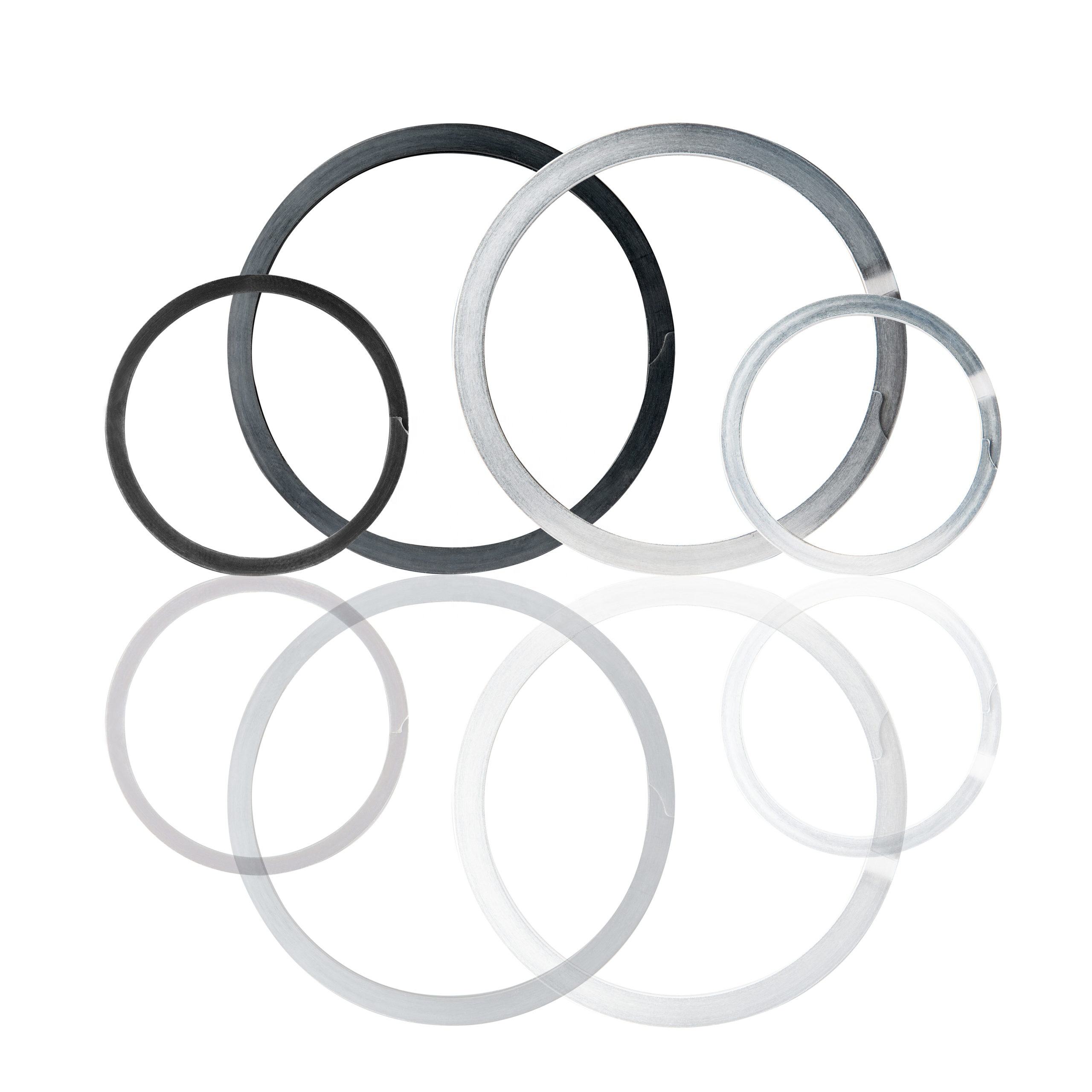

Spiral Retaining Ring

Spiral Retaining Ring

Standard Spec :Customized

Diameter :φ5-φ1000

Material:Spring Steel ,Alloy Steel ,Stainless Steel

Double Wound Spiral Retaining Rings: Material, Processing, Applications & Installation

Material Options

- Stainless Steel (e.g., SUS304, 316): Ideal for corrosive environments (marine, chemical).

- High-Carbon Steel (e.g., SAE 1074/1095): Offers superior strength and fatigue resistance.

- Alloy Steel (e.g., 51CrV4): Enhanced toughness for extreme loads and temperatures.

- Surface Treatments: Zinc plating, Dacromet coating, or passivation to boost durability.

Processing Techniques

- Spiral Winding: Precision coiling of dual-layer metal strips to form interlocking helical structures.

- Heat Treatment: Quenching and tempering (HRC 45-55) to optimize hardness and elasticity.

- Grinding/Finishing: Deburring and edge smoothing (Ra ≤1.0μm) to prevent component damage.

- Coating Application: Electroplating or epoxy coatings for corrosion/wear resistance.

Key Processing Considerations

- Dimensional Accuracy: Tight tolerances (±0.03mm) on inner/outer diameters (per ISO 286).

- Stress Distribution: Uniform winding tension to avoid weak points or deformation.

- Fatigue Testing: Cyclic load simulations (ASTM E606) to validate performance under vibration.

- Layer Bonding: Ensure seamless adhesion between dual layers to prevent delamination.

Applications

- Automotive Transmissions: Secures gears and bearings under high torque and vibration.

- Aerospace Actuators: Lightweight retention in landing gear and flight control systems.

- Heavy Machinery: Axial fixation for rotating shafts in mining and construction equipment.

- Energy Systems: Used in turbines and pumps for thermal stability (up to 300°C).

Installation Guidelines

- Tool Selection: Use spiral ring pliers for controlled expansion/compression during installation.

- Groove Alignment: Ensure the ring seats fully into the machined groove without over-stressing.

- Lubrication: Apply dry-film lubricant on contact surfaces to reduce friction and wear.

- Post-Installation Check: Verify ring engagement and inspect for cracks or misalignment.

Frequently Asked Questions

A: Normally, we make a 30% deposit after Pl confirmation and a 70% balance before shipment. lf order amountis too small, we can also change to 100% deposit in order to save bank handling charge.

A: A pre-bulk sample check can solve this problem to the largest extent. We will arrange production according to the pre-bulk sample quality standard after your confirmation of the samples.

A: We are not only a trading company but also a manufacturer. Our factory mainly focuses on mold design and quality inspection. Our bulk production may come from the factories we have worked with for a long time, and they are all ISO9001 certified. Through this cooperation model, we can not only ensure product quality and service, but also satisfy the diversified product needs of customers, and the price is more advantageous.

A: Yes,we are very glad to offer you samples.

However the express courier cost from our company to your required address will be upon your account.

Usually we use DHL, UPS, FEDEX or EMS as the courier.

It will take 3-7 days to arrive many Europe countries and North America.

Which express courier we will use, it’s up to your convenient or the express charge.

A: No,just part of our capable categories have been showed in our site.

If you are looking for relative industrial products, please feel free to contact us.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.