A: It depends.If we have bulk goods in stock, we can ship goods within 3 days after the QC process. If we don’t have stock, normally it takes 7-15 days for OEM samples and 20-30 days for bulk goods. If it refers to opening the new mold, it takes an extra 7-15 days to make the mold.

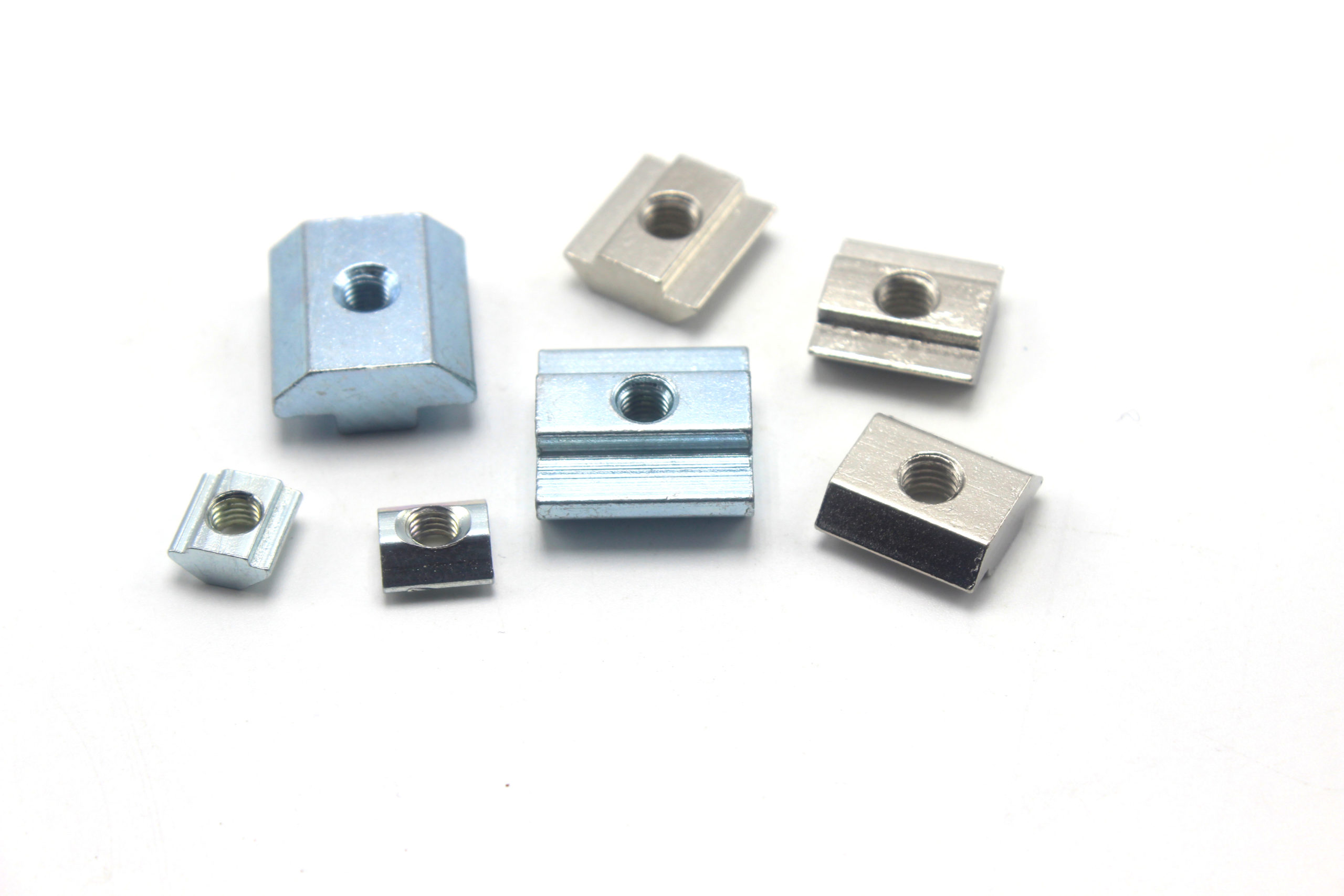

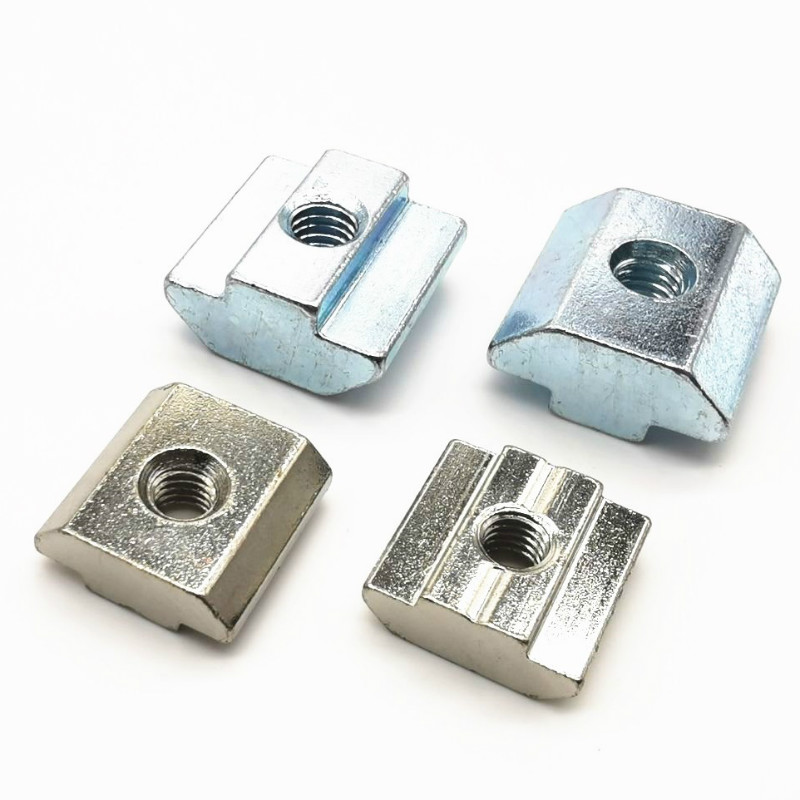

Slide Nut

Slide Nut

Standard Spec :YJT3042

Diameter :M4-M8

Length:6-100mm

Material:Carbon Steel ,Alloy Steel ,Stainless Steel

Class:4, 6, 8, A2-70, A4-70

Slider Nuts (Adjustable Slide Nuts): Overview

Material:

- Common materials:

- Carbon steel: Grade 8.8/10.9 (heat-treated for strength), zinc-plated or galvanized.

- Stainless steel: 304/316 (corrosion resistance in harsh environments).

- Aluminum alloy: Lightweight for low-load applications (e.g., furniture, prototyping).

- Surface treatments: Zinc plating, Dacromet coating, anodizing (aluminum), or passivation (stainless steel).

Manufacturing Process:

- Cold Stamping: Forms the nut body from sheet metal or wire, creating the sliding channel.

- Thread Rolling/Tapping: Precision internal threads (metric/SAE) for bolt compatibility.

- Slot Machining: CNC milling or stamping of grooves/slots for alignment in T-tracks.

- Heat Treatment (steel variants): Quenching and tempering for hardness (HRC 20-35).

- Surface Finishing: Coating or polishing for corrosion resistance and smooth sliding.

Key Production Considerations:

- Slot width/depth: Must match T-slot or rail dimensions (e.g., 6mm, 10mm profiles).

- Thread concentricity: Ensures smooth engagement with bolts without cross-threading.

- Sliding tolerance: Tight clearance (±0.1mm) for smooth movement yet minimal play.

- Coating uniformity: Prevents friction or jamming in sliding channels.

Applications:

- CNC machines: Securing clamps, fixtures, and tools on T-slot tables.

- Industrial automation: Linear guides, robotic arms, and conveyor systems.

- 3D printers: Modular frame assembly and component mounting.

- Furniture systems: Adjustable shelving, workbenches, and ergonomic setups.

- Prototyping: Rapid repositioning of parts in R&D or DIY projects.

Installation:

- Slot insertion: Slide the nut into the T-track or rail channel until aligned with the desired position.

- Bolt threading: Insert a bolt through the component and into the slider nut’s threaded hole.

- Tightening: Use a wrench to tighten the bolt, locking the nut in place against the track walls.

- Adjustment: Loosen the bolt, reposition the nut, and retighten for flexible configurations.

- Torque control: Follow manufacturer specs (e.g., 10–50 Nm for M6–M12 nuts).

Note:

- Compatibility: Ensure nut dimensions match the rail system (e.g., metric vs. imperial slots).

- Load limits: Use steel variants for heavy loads; aluminum for lightweight assemblies.

- Maintenance: Clean tracks periodically to prevent debris buildup affecting sliding.

Ideal for engineers, makers, and manufacturers needing modular, reconfigurable fastening in precision systems.

Key Terms: Slider Nuts, T-Slot Nuts, DIN 1470, Modular Fastening, Linear Motion Systems.

Character Count: Optimized for technical clarity and brevity.

Frequently Asked Questions

A: Normally, we make a 30% deposit after Pl confirmation and a 70% balance before shipment. lf order amountis too small, we can also change to 100% deposit in order to save bank handling charge.

A: A pre-bulk sample check can solve this problem to the largest extent. We will arrange production according to the pre-bulk sample quality standard after your confirmation of the samples.

A: We are not only a trading company but also a manufacturer. Our factory mainly focuses on mold design and quality inspection. Our bulk production may come from the factories we have worked with for a long time, and they are all ISO9001 certified. Through this cooperation model, we can not only ensure product quality and service, but also satisfy the diversified product needs of customers, and the price is more advantageous.

A: Yes,we are very glad to offer you samples.

However the express courier cost from our company to your required address will be upon your account.

Usually we use DHL, UPS, FEDEX or EMS as the courier.

It will take 3-7 days to arrive many Europe countries and North America.

Which express courier we will use, it’s up to your convenient or the express charge.

A: No,just part of our capable categories have been showed in our site.

If you are looking for relative industrial products, please feel free to contact us.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.