As a leading enterprise in precision manufacturing, our company has established an industry-leading intelligent manufacturing system:

Production Capacity

• Equipment Portfolio: Equipped with 20+ intelligent cold stamping presses and 15 high-speed precision stamping machines, enabling large-scale production of basic components

• CNC Cluster: Operates over 100 full-function CNC turning centers for automated high-precision rotational component processing

• Specialized Machinery: Integrated with 20+ types of specialized equipment including thread rolling machines, precision planer mills, and cylindrical grinders

Process Capabilities

• Surface Treatment: Houses a fully automated heat treatment line mastering core thermal processes such as carburizing quenching and normalization

• Corrosion Protection: Equipped with an automated electroplating zinc production line certified to ISO 12944 international corrosion protection standards

Quality Assurance

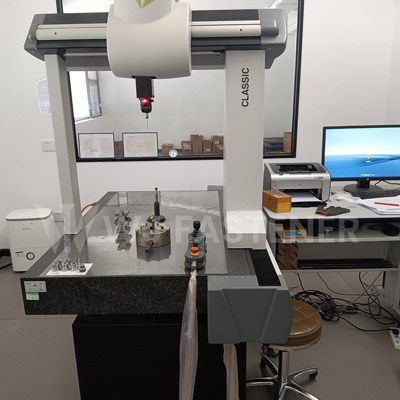

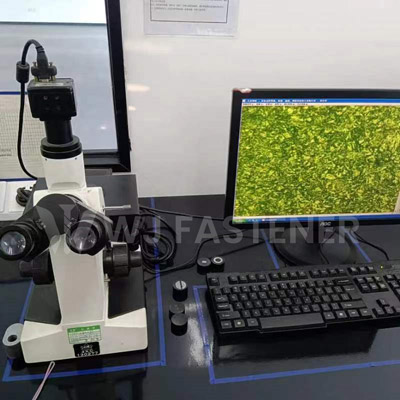

Leveraging advanced ERP intelligent control systems and coordinate measuring machines (CMM), we have built a digital quality management system covering raw material inspection through final product testing.

This technological and process superiority enables us to deliver high-quality precision components and solutions to global customers.