A: It depends.If we have bulk goods in stock, we can ship goods within 3 days after the QC process. If we don’t have stock, normally it takes 7-15 days for OEM samples and 20-30 days for bulk goods. If it refers to opening the new mold, it takes an extra 7-15 days to make the mold.

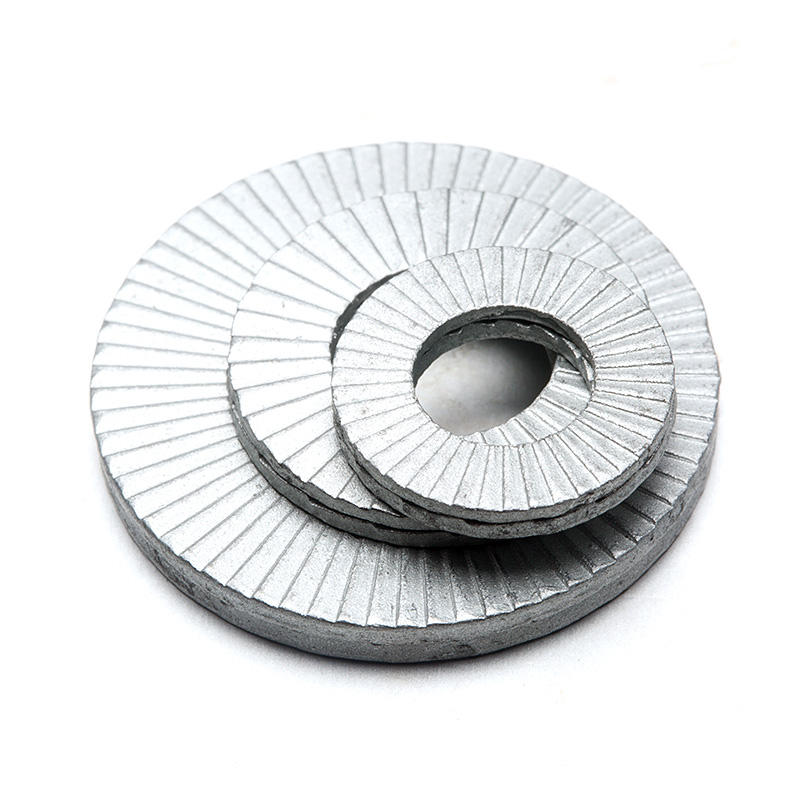

Double-Lock Washer

Double-Lock Washer

Standard Spec :DIN25201

Diameter :M6-M100(8#-4”)

Material:Carbon Steel ,Alloy Steel ,Stainless Steel

Class:4.8,5.8,6.8,8.8,10.9,G2,G5

Double Split Lock Washers:

Materials:

- Carbon steel (common for general use, heat-treated for spring properties), stainless steel (AISI 304/316 for corrosion resistance), alloy steel (high-strength applications).

- Surface treatments: Zinc plating, phosphate coating, or Dacromet for rust prevention and improved wear resistance.

Manufacturing Process:

- Stamping: Cut and shape dual split-spring profiles from metal sheets.

- Heat Treatment: Quenching and tempering to achieve elasticity and fatigue resistance.

- Forming: Create two interlocking split-spring layers using precision dies.

- Surface Finishing: Coatings applied to enhance durability and reduce friction.

Key Production Considerations:

- Spring Tension Balance: Ensure uniform elasticity between the dual split layers.

- Edge Sharpness: Maintain crisp split edges to maximize grip on mating surfaces.

- Alignment: Precise stacking of the two split layers to prevent overlap defects.

- Deburring: Remove sharp edges to protect fastener threads and components.

Applications:

- Machinery: Secure bolts in high-vibration equipment (e.g., pumps, compressors).

- Automotive: Critical assemblies like engine mounts, drivetrain components.

- Aerospace: Fastener retention in vibration-prone aircraft systems.

- Heavy Equipment: Bolted joints in construction or mining machinery.

- Electronics: Stabilize fasteners in devices exposed to thermal cycling.

Installation:

- Placement: Position between the nut/bolt head and the mating surface.

- Orientation: Align splits to face opposite directions for maximum spring tension.

- Torque: Tighten to manufacturer-specified torque to compress both layers evenly.

- Inspection: Ensure both split layers engage fully without twisting or misalignment.

Advantages:

- Enhanced Loosening Resistance: Dual spring action provides redundant locking force.

- Reusable: Retains elasticity if not over-compressed during installation.

- Space-Efficient: Compact design suits tight assemblies.

Note:

- Avoid over-tightening, which may flatten the dual springs and reduce effectiveness.

- Replace washers if splits are deformed or coatings are damaged.

- Pair with threadlockers for extreme vibration environments.

Frequently Asked Questions

A: Normally, we make a 30% deposit after Pl confirmation and a 70% balance before shipment. lf order amountis too small, we can also change to 100% deposit in order to save bank handling charge.

A: A pre-bulk sample check can solve this problem to the largest extent. We will arrange production according to the pre-bulk sample quality standard after your confirmation of the samples.

A: We are not only a trading company but also a manufacturer. Our factory mainly focuses on mold design and quality inspection. Our bulk production may come from the factories we have worked with for a long time, and they are all ISO9001 certified. Through this cooperation model, we can not only ensure product quality and service, but also satisfy the diversified product needs of customers, and the price is more advantageous.

A: Yes,we are very glad to offer you samples.

However the express courier cost from our company to your required address will be upon your account.

Usually we use DHL, UPS, FEDEX or EMS as the courier.

It will take 3-7 days to arrive many Europe countries and North America.

Which express courier we will use, it’s up to your convenient or the express charge.

A: No,just part of our capable categories have been showed in our site.

If you are looking for relative industrial products, please feel free to contact us.

Get Quote Now!

Welcome to discuss your purchasing requirements with our customer service.